2022 China New Design Belt Conveyor Uses - TD75 type fixed belt conveyor – Yongxing

2022 China New Design Belt Conveyor Uses - TD75 type fixed belt conveyor – Yongxing Detail:

Technical characteristics and main parameters

The bulk density of the material can be transported by the conveyor in the range of 0.5-2.5T /m3.

This series conveyor is divided into: 500, 650, 800, 1000, 1200, 1400mm and other six specifications according to the bandwidth. The belt speed is 0.8m /s, 1.0m /s, 1.25m /s, 1.6m /s, 2.0m/s, 2.5m/s, 3.15m/s, 4.0m/s, etc. See the table on the following page for maximum throughput.

Driving device: the power range is 2.2~55Kw when the electric drum is used to drive, which can save space, but the ambient temperature should not exceed 40℃. When the power is greater than 55Kw, the motor, reducer and drum should be used to drive separately. The surface of the driving drum has three forms: bare steel surface, herringbone and rhombus rubber surface.

To the drum split surface and glue surface two.

Roller is made of seamless steel pipe, types: groove shape, flat shape, aligning, buffer four.

Tension device: Screw tensioning device is suitable for short length (< 100m), stroke of 500mm, 800mm, 1000mm three kinds; Vertical hammer tensioning device can automatically compensate the elongation of conveyor belt with the change of tension by gravity; Heavy hammer car type tensioning device is suitable for conveyors with long distance and large power. Its tensioning stroke is 2, 3 and 4M. Fixed winch tensioning device is used for belt conveyors with long distance and large tensioning force (30~150KN), long distance and large volume, and the maximum tensioning journey can reach 16m.

There are two kinds of head cleaner and empty segment cleaner.

Electrical protection can be provided with: conveyor belt deviation detector; Conveyor belt slip detector; Conveyor belt longitudinal tear signal detector; Material level control detector, etc.

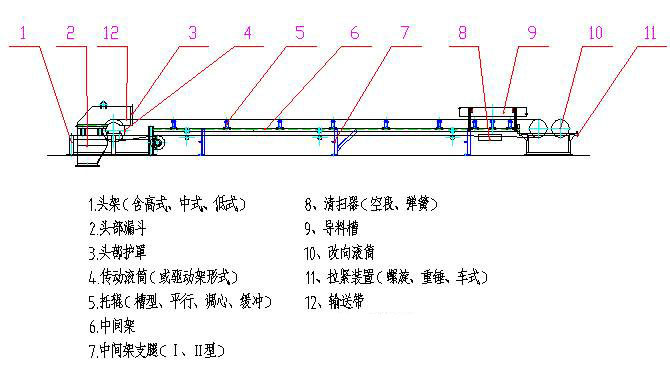

Structure diagram of TD75 belt conveyor

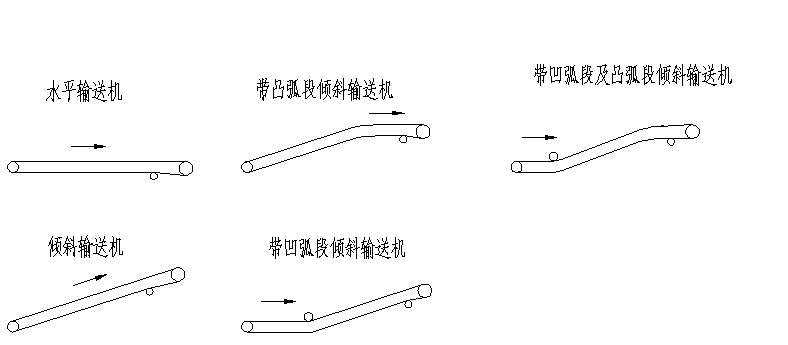

Basic layout of TD75 belt conveyor

Conveyor capacity of belt conveyor

| sectionIn the form of | Tape speed(m/s) | Bandwidth B (mm) | |||||||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | ||||||

| Conveying capacity Q (t/h) | |||||||||||

| Trough type | 0.81.0 | 7897 | 131164 | –278 | –435 | –655 | –891 | ||||

| 1.251.6

2.0 2.5 3.15 4.0 |

122156

191 232 – – |

206264

323 391 – – |

348445

546 661 824 – |

544696

853 1033 1233 – |

8191048

1284 1556 1858 2202 |

11151427

1748 2118 2528 2996 |

|||||

| flat | 0.81.0

1.25 1.6 2.0 2.5 |

4152

66 84 103 125 |

6788

110 142 174 211 |

118147

184 236 289 350 |

–230

288 368 451 546 |

–345

432 553 677 821 |

–469

588 753 922 1117 |

||||

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for 2022 China New Design Belt Conveyor Uses - TD75 type fixed belt conveyor – Yongxing , The product will supply to all over the world, such as: Montreal, Sierra Leone, UK, You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.