Chinese Professional Belt Machine - ZG type electromagnetic vibration feeder – Yongxing

Chinese Professional Belt Machine - ZG type electromagnetic vibration feeder – Yongxing Detail:

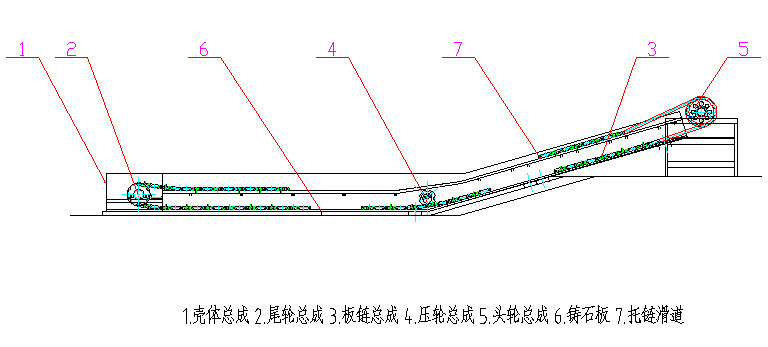

Structure diagram of ZBC heavy plate chain desagger

Host selection

| type | Productivity calculation Bulk density (T/m3) | use |

| basic | 1.6 | No special requirements for material feeding |

| The vibration mode | 1.6 | If the configuration space is insufficient, it can be installed and used. The rest is the same as the basic model |

| enclosed | 1.6 | Fragile particles, large dust and volatile material feeding |

| Light trough type | 1.0 | Light material feeding with smaller specific gravity |

| The router type | Given by coal blending and coal preparation conditions | The thin material layer is uniformly fed |

| Wide groove | Given by coal blending and coal preparation conditions | Mainly used for coal preparation, can also be used for feeding to screening equipment |

When the actual bulk density is greater or less than the above calculated bulk density, the productivity shall be converted according to the actual bulk density of the material. For materials with particle size less than 1mm, the conveying speed decreases. For wet and viscous materials with moisture content more than 10%, the material layer thickness exceeds a certain value, which will hinder the normal feeding. It is recommended that H= (1/3-1/4) tank height. Our factory can design and manufacture products with special requirements and specifications.

Matching control box

| Feed model number | Common control box model | The style | Model of amplitude stabilizing control box | The style | Feed model number | Common control box model | The style | Model of amplitude stabilizing control box | The style |

| ZG1 | XKZ-5G2 | exo | ZWKX-I-I ZWKX-5G2 |

Taiwan hung | ZG8, ZG9 | XKZ-200G3 | desktop | ZWKX-II-2 ZWKX-200G3 |

Taiwan hung |

| ZG2, ZG3 | XKZ-10G2 | exo | ZWKX-I-1 ZWKX-10G2 |

Taiwan hung | ZG10, ZG11 | XKZ-20G3 | desktop | ZWKX-II-3 ZWKX-200G3 |

Taiwan hung |

| ZG4, ZG5 | XKZ-20G2 | exo | ZWKX-I-3 ZWKX-20G2 |

Taiwan hung | ZG5K(1-4) | XKZ-50G2 | exo | – | Taiwan hung |

| ZG6, ZG7 | XKZ-50G3 | exo | ZWKX-II-1 ZWKX-50G3 |

Taiwan hung | – | – | – |

ZG type electromagnetic vibration feeder main technical parameters

| type | model | Productivity (t/h) | Feed size (mm) | Double amplitude (mm) | Vibration frequency (times/min) | Supply voltage (V) | Current (A) | Active power (KW) | ||

| The level of | -10° | Working current | According to current | |||||||

| basic | ZG1 | 5 | 7 | 50 | 1.75 | 3000 | 220 | 1.34 | 1.0 | 0.06 |

| ZG2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | ||||

| ZG3 | 25 | 35 | 75 | 4.6 | 3.8 | 0.20 | ||||

| ZG4 | 50 | 70 | 100 | 8.4 | 7.0 | 0.45 | ||||

| ZG5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| ZG6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | ||

| ZG7 | 250 | 350 | 300 | 24.6 | 20 | 2.5 | ||||

| ZG8 | 400 | 560 | 300 | 39.4 | 32 | 4.0 | ||||

| ZG9 | 600 | 840 | 500 | 47.6 | 38.6 | 5.5 | ||||

| ZG10 | 750 | 1050 | 500 | 39.4X2 | 32X2 | 4.0X2 | ||||

| ZG11 | 1000 | 1400 | 500 | 47.6X2 | 38.6X2 | 5.5X2 | ||||

| The vibration mode | ZG3S | 25 | 35 | 75 | 1.75 | 220 | 4.6 | 3.8 | 0.2 | |

| ZG4S | 50 | 70 | 100 | 8.4 | 7.0 | 0.45 | ||||

| ZG5S | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | ||||

| ZG6S | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | ||

| ZG7S | 250 | 350 | 250 | 24.6 | 20 | 2.5 | ||||

| ZG8S | 400 | 560 | 300 | 39.4 | 32 | 4.0 | ||||

| enclosed | ZG1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 1.0 | 0.06 | |

| ZG2F | 8 | 11.2 | 40 | 3.0 | 2.3 | 0.15 | ||||

| ZG3F | 20 | 28 | 60 | 4.6 | 3.8 | 0.20 | ||||

| ZG4F | 40 | 50 | 60 | 8.4 | 7.0 | 0.45 | ||||

| ZG5F | 80 | 112 | 80 | 12.7 | 10.6 | 0.65 | ||||

| ZG6F | 120 | 168 | 80 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | ||

| Light trough type | ZG5Q | 100 | 140 | 200 | 1.75 | 220 | 12.7 | 10.6 | 0.65 | |

| ZG6Q | 150 | 200 | 250 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | ||

| ZG7Q | 250 | 350 | 300 | 24.6 | 20 | 2.5 | ||||

| ZG8Q | 400 | 560 | 350 | 39.4 | 32 | 4.0 | ||||

| The router type | ZG5P | 50 | 140 | 100 | 1.75 | 220 | 12.7 | 10.6 | 0.65 | |

| ZG6P | 75 | 210 | 300 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | ||

| ZG7P | 125 | 350 | 350 | 24.6 | 20 | 2.5 | ||||

| Wide groove | ZG5K1 | – | 200 | 100 | 1.5 | 220 | 12.7X2 | 10.6X2 | 0.65X2 | |

| ZG5K2 | – | 240 | 100 | |||||||

| ZG5K3 | – | 270 | 100 | |||||||

| ZG5K4 | – | 300 | 100 | |||||||

Product detail pictures:

Related Product Guide:

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Chinese Professional Belt Machine - ZG type electromagnetic vibration feeder – Yongxing , The product will supply to all over the world, such as: Detroit, Lesotho, Georgia, With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart". We will serve the domestic and foreign businessmen with sincere dedication, and let us create bright future together with you!

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Write your message here and send it to us