Fast delivery Chain Conveyor - GX/LS powder materical screw conveyor – Yongxing

Fast delivery Chain Conveyor - GX/LS powder materical screw conveyor – Yongxing Detail:

2PGC double tooth roller crusher structure diagram

Specifications

LS, GX type screw conveyor specifications and technical parameters see the table below, length from 3.5m to 80m, standard interval 0.5m first gear, drive device is divided into two kinds, C1 method — screw conveyor length is less than 35m single end drive, C2 method — screw conveyor length is greater than 35m double end drive.

Considerations for selection:

A. Spiral diameter

The minimum spiral diameter shall be determined by the rotating speed and the conveying capacity, and meet the following conditions: for conveying bulk materials, the spiral diameter D shall be at least 10 times the maximum side length of particles. If the content of large particles is small, a smaller spiral diameter can be selected, but at least 4 times the maximum side length of particles.

B, rotational speed

The speed of screw conveyor is not allowed to be too large, otherwise the material is transported by strong centrifugal force, so that the conveying process is affected, according to JB/T7679-95 “Screw conveyor” standard each specification has 4 kinds of speed for selection.

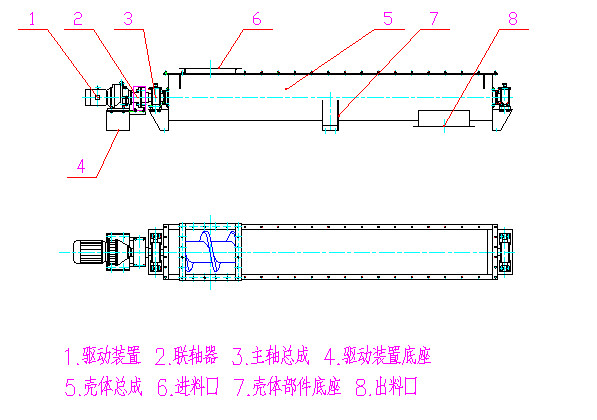

Schematic diagram of screw conveyor structure

Main technical parameters: (N: speed r/min Q: throughput m3/h)

| specifications | LS100 | LS160 | LS200 | LS250 | LS315 | LS400 | LS500 | LS630 | LS800 | LS1000 | LS1250 | |

| Diameter of helix (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 | |

| Technical parameters | N | 140 | 112 | 100 | 90 | 80 | 71 | 63 | 50 | 40 | 32 | 25 |

| Q | 2.2 | 8 | 14 | 24 | 34 | 64 | 100 | 145 | 208 | 300 | 388 | |

| N | 112 | 90 | 80 | 71 | 63 | 56 | 50 | 40 | 32 | 25 | 20 | |

| Q | 1.7 | 7 | 12 | 20 | 26 | 52 | 80 | 116 | 165 | 230 | 320 | |

| N | 90 | 71 | 63 | 56 | 50 | 45 | 40 | 32 | 25 | 20 | 16 | |

| Q | 1.4 | 6 | 10 | 16 | 21 | 41 | 64 | 94 | 130 | 180 | 260 | |

| N | 71 | 50 | 50 | 45 | 40 | 36 | 32 | 25 | 20 | 16 | 13 | |

| Q | 1.1 | 4 | 7 | 13 | 16 | 34 | 52 | 80 | 110 | 150 | 200 | |

| Specifications and Models (mm) | GX150 | GX200 | GX250 | GX300 | GX400 | GX500 | GX600 | GX700 | |

| Diameter of helix (mm) | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | |

| Pitch (mm) | entity | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 |

| entity | 120 | 160 | 200 | 240 | 320 | 400 | 480 | 560 | |

| Speed (r/min) | 75 | 75 | 75 | 60 | 60 | 48 | 48 | 48 | |

| Throughput (m3/h) | 3.6 | 8.5 | 10.4 | 18 | 42.5 | 67.7 | 117 | 185.7 | |

Product detail pictures:

Related Product Guide:

Always customer-oriented, and it's our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for Fast delivery Chain Conveyor - GX/LS powder materical screw conveyor – Yongxing , The product will supply to all over the world, such as: Ghana, Mauritania, Macedonia, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.