PCH series ring hammer crusher

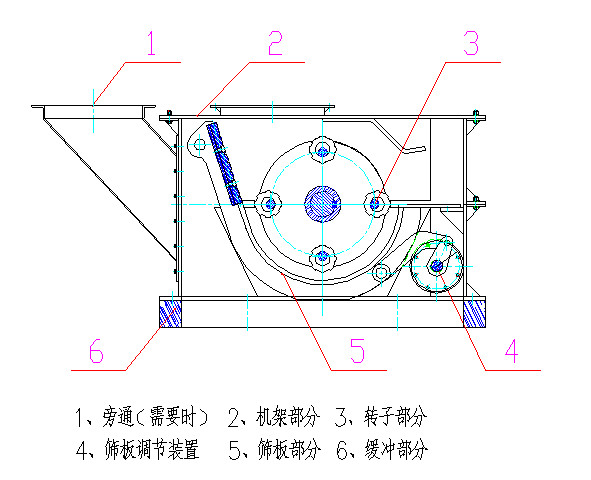

PCH series ring hammer crusher structure diagram

PCH series ring hammer crusher main technical parameters

| model | Rotor × Diameter length /mm | Rotor speed r/min | Maximum feed block size /mm | Discharging particle size /mm | Production capacity/T · H1 | motor | Appearance of size(length x width x height) /mm | |

| model | Power/kw | |||||||

| PCH-0402 | 400×200 | 960 | 200 | ≤30 | 8~12 | Y132M2-6 | 5.5 | 810×890×560 |

| PCH-0404 | 400×400 | 970 | 16~25 | Y160L-6 | 11 | 980×890×570 | ||

| PCH-0604 | 600×400 | 970 | 22~23 | Y180L-6 | 15 | 1050×1270×800 | ||

| PCH-0606 | 600×600 | 980 | 30~60 | Y225M-6 | 30 | 1350×1270×820 | ||

| PCH-0808 | 800×800 | 740 | 300 | 75~105 | Y280M-8 | 45 | 1750×1620×1080 | |

| PCH-1010 | 1000×1000 | 160~200 | Y315M2-8 | 90 | 2100×2000×1340 | |||

| 200~245 | Y315M3-8 | 110 | ||||||

| PCH-1016 | 1000×1600 | 300~350 | JS128-8 | 155 | 3700×2000×1350 | |||

| 400~500 | Y400-8 | 220 | ||||||

| PCH-1216 | 1200×1600 | 740 | 350 | 500~620 | Y400-8 | 280 | 3100×2800×1750 | |

| 620~800 | Y450-8 | 355 | ||||||

Note:

1. Discharge particle size can be arbitrarily selected within 3 ~ 60mm. When the discharging particle size is not greater than 15mm, the production capacity should be 60% of the value listed in the table; When the discharging particle size is 3mm and the material surface moisture is not more than 10%, the production capacity should be 30% of the value listed in the table.

2. When ordering, it is necessary to indicate the name of the broken material and the discharging size, the required equipment model and installation form (left or right mounted), the motor power and voltage, whether the hopper or bypass groove is needed.

Write your message here and send it to us