PCKW series reversible non – blocking fine crusher

Performance characteristics

(1) no grate to overcome the problem of material humidity blockage.

(2) The rotor can be positive and reverse, improve the utilization rate of the hammer head, reduce the frequency of replacing the hammer head, improve the work efficiency, increase the output of the system.

(3) the use of heavy hammer head, increase the strike force, the production capacity is the same as the specifications of hammer broken 2 times.

(4) The clearance of discharge port can be adjusted to ensure the uniformity of discharging particle size, so that the material less than 8mm reaches more than 95%.

(5) the cavity plate can be opened to replace the lining plate easily. The mainframe uses hydraulic cylinders.

(6) The machine is reliable, easy to operate and easy to maintain.The machine makes full use of the impact crusher hitting force,Characteristics of high crushing efficiency,Can be widely used in steel mills, power plants, cement plants and other large and medium-sized enterprises on the material crushing operation.

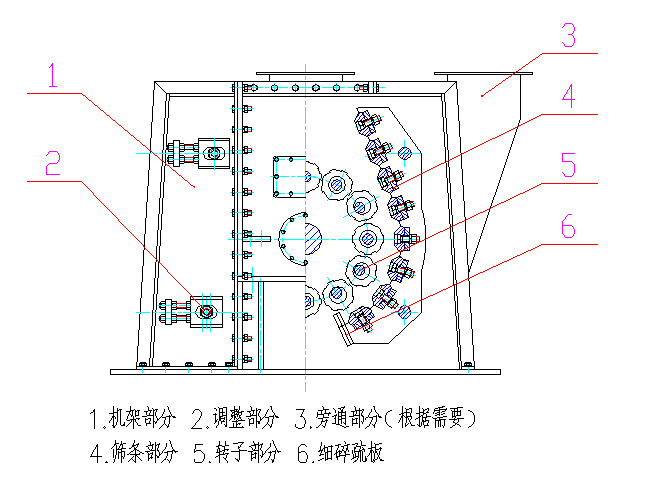

Structure diagram of PCKW series reversible non-blocking fine crusher

Basic parameters

| model | PCKW0806 | PCKW0809 | PCKW1012 | PCKW1214 | PCKW1414 | PCKW1416 | PCKW1618 |

| Rotor working diameter X length (mm) | 800X600 | 800 X 900 | 1000X1200 | 1200X1400 | 1400X1400 | 1400X1600 | 1600X1800 |

| The rotor speed | 966 | 970 | 980 | 981 | 740 | 750 | 675 |

| Inlet size (mm) | 300X600 | 300X800 | 300X1200 | 400X1450 | 600X1450 | 400X1650 | 550X1800 |

| Maximum feed size (mm) | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Discharge particle size (mm) | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 | 3~8 |

| Processing capacity (t/h) | 10~40 | 20~60 | 40~100 | 60~160 | 80~180 | 120~300 | 240~320 |

| Motor power (Kw) | 45~55 | 45~75 | 90~132 | 160~185 | 185~220 | 185~220 | 220~280 |