Top Quality Bucket Elevator Drum Pulley - NE/NES vertical conveyor bucket elevator – Yongxing

Top Quality Bucket Elevator Drum Pulley - NE/NES vertical conveyor bucket elevator – Yongxing Detail:

Structural features and working principle

NE, NSE series bucket elevator is composed of tail parts, head parts, bucket chain components, driving device components, fully closed casing, no material leakage when the equipment is running, lifting conveyor chain using punching plate chain, divided into single chain and double chain two types of arrangement, the head is set up with backstop, backstop reliable. The inlet and outlet of the equipment and the lifting height can be flexibly designed and arranged according to the technological requirements.

The material is uniformly introduced into the hopper fixed on the lifting chain for continuous closed operation through the inlet and outlet of the equipment, and the material is lifted from the inlet of the tail to the outlet of the nose to discharge, realizing single point of feed, single point of gravity type or mixed discharge.

The lifting conveyor chain adopts the hammer lever type automatic tensioning device to ensure that the lifting chain always maintains the appropriate tensioning device during operation, so that the equipment is in the best running state.

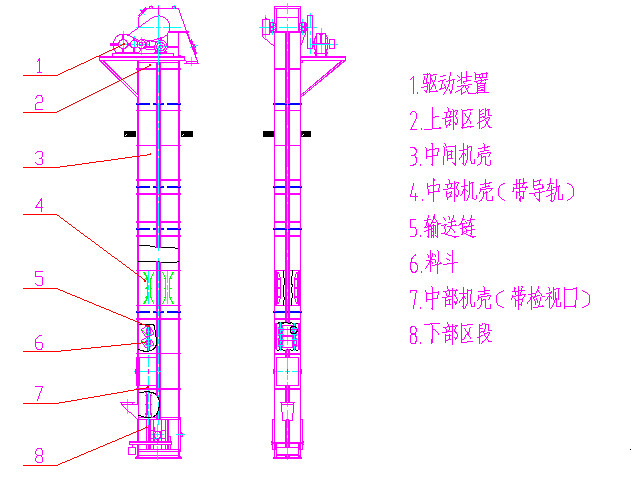

NE, NSE type bucket elevator structure diagram

NE type bucket elevator main technical parameters

| model | Throughput m3 / h | Bucket volume L | Bucket mm wide | The bucket from mm | Dou speed m/s | Spindle speed r/min | Maximum width of material mm |

| NE15 | 15 | 2.5 | 250 | 203.2 | 0.5 | 19.5 | – |

| NE30 | 32 | 7.8 | 300 | 304.8 | 0.5 | 16.45 | 65 |

| NE50 | 60 | 14.7 | 300 | 304.8 | 0.5 | 16.45 | 65 |

| NE100 | 110 | 35 | 400 | 400 | 0.5 | 14.13 | 95 |

| NE150 | 170 | 52.2 | 600 | 400 | 0.5 | 14.13 | 95 |

| NE200 | 210 | 84.6 | 600 | 500 | 0.5 | 10.9 | 125 |

| NE300 | 320 | 127.5 | 600 | 500 | 0.5 | 10.9 | 125 |

| NE400 | 380 | 182.6 | 700 | 600 | 0.5 | 8.3 | 145 |

| NE500 | 470 | 260.9 | 700 | 700 | 0.5 | 7.1 | 165 |

| NE600 | 600 | 300.2 | 700 | 700 | 0.5 | 7.1 | 165 |

| NE800 | 800 | 501.3 | 800 | 800 | 0.5 | 7.1 | 195 |

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for Top Quality Bucket Elevator Drum Pulley - NE/NES vertical conveyor bucket elevator – Yongxing , The product will supply to all over the world, such as: Mozambique, Stuttgart, United States, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.